Features

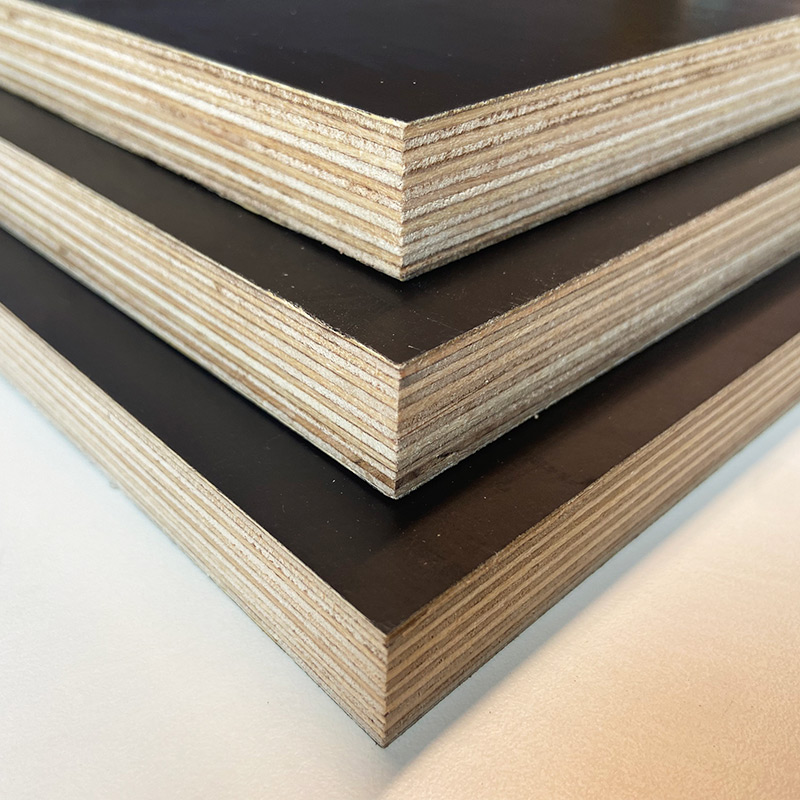

-100% birch veneer

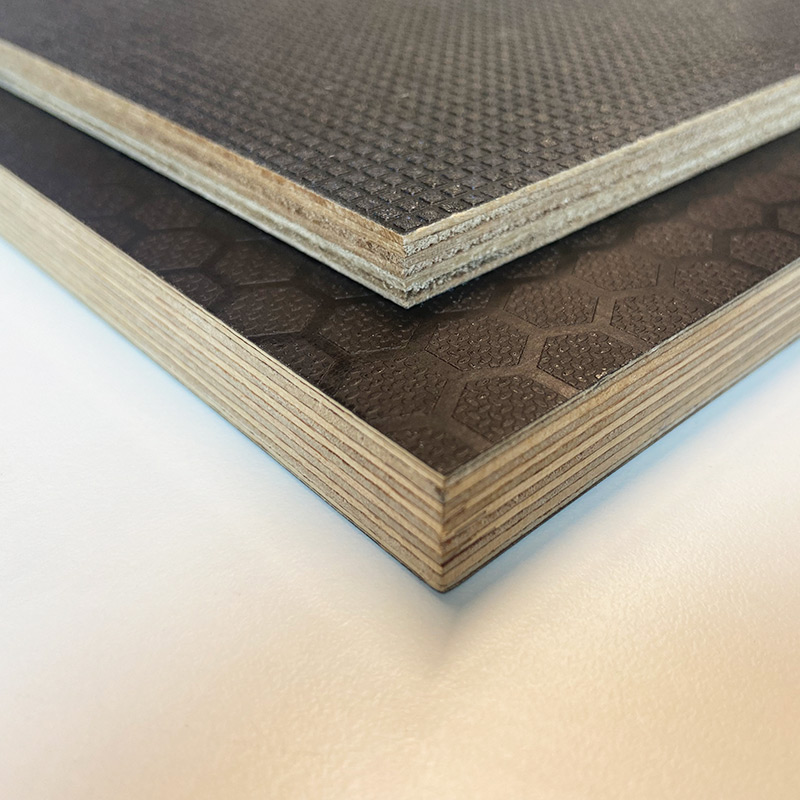

-superlative hardness of a surface

-good resistance to most aggressive environments, including chemicals

-nice texture of birch wood

-higher water-resistance

-fine and smooth sanded surface

-fast installation and easy processing

-Superior strength and stability

-Superior resistance to loss of bond strength with time

Applications

-Concrete Formwork

-Vehicle bodies

-Container floors

-Furniture

-Moulds

Specifications

| Dimensions, mm | 1220x2440,1250x2500,1220x2500 | |||||||

| Thickness, mm | 6,8,9,12,15,18,21,24,27,30,35 | |||||||

| Surface type | smooth/smooth(F/F) | |||||||

| Film colour | brown, black, red | |||||||

| Film density,g/m2 | 220g/m2,120g/m2 | |||||||

| Core | pure birch | |||||||

| Glue | phenolic WBP (type dynea 962T) | |||||||

| Formaldehyde emission class | E1 | |||||||

| Water resistance | high | |||||||

| Density, kg/m3 | 640-700 | |||||||

| Moisture content, % | 5-14 | |||||||

| Edge sealing | acryl-based water resistant paint | |||||||

| Certification | EN 13986, EN 314, EN 635, EN 636, ISO 12465, KS 301, etc. | |||||||

Strength indicators

| Ultimate static bending strength,min Mpa | along the grain of face veneers | 60 | ||||||

| against the grain of face veneers | 30 | |||||||

| Static bending elasticity modulus, min Mpa | along the grain | 6000 | ||||||

| against the grain | 3000 | |||||||

Number of Plies & tolerance

| Thickness(mm) | Number of Plies | Thickness tolerance |

| 6 | 5 | +0.4/-0.5 |

| 8 | 6/7 | +0.4/-0.5 |

| 9 | 7 | +0.4/-0.6 |

| 12 | 9 | +0.5/-0.7 |

| 15 | 11 | +0.6/-0.8 |

| 18 | 13 | +0.6/-0.8 |

| 21 | 15 | +0.8/-1.0 |

| 24 | 17 | +0.9/-1.1 |

| 27 | 19 | +1.0/-1.2 |

| 30 | 21 | +1.1/-1.3 |

| 35 | 25 | +1.1/-1.5 |