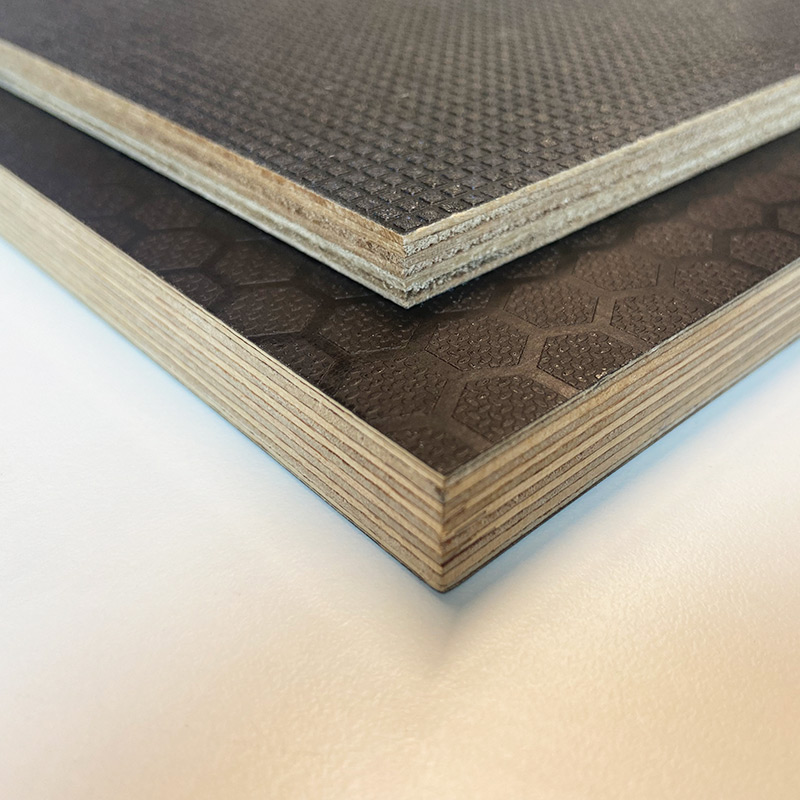

Anti-slip film faced plywood is a film-coated plywood with anti-slip pattern on sides, it is made in a similar fashion to regular smooth phenolic film faced panels with the additional process of applying a patterned, metallic press to the face to create the appropriate design.

The wear side has a rough antislip pattern and the reverse side is smooth film or raw plywood as needed.The edges of anti-slip plywood are sealed 3 times with waterpoof paint.

It's highly resistant to slip and high durability, so it's designed for use as flooring in the transportation industry and other applications where slip resistance. It offers different choice of anti-slip patterns on the surface, and the heavy duty hex pattern face gives superlative slip resistance.

Features

-High wear resistance

-High slip resistance (R10)

-High load bearing capacity

-Heat and cold resistant -30°C / +80°C

-Decorative patterns

Applications

-Construction ground

-Compartment floors

-Vehicle body building

-Automotive

-Stages

-Flight cases

-Horseboxes

-Platforms

-Walkways

Specifications

| Dimensions, mm | 1220x2440,1250x2500,1220x2500 | |||||||

| Thickness, mm | 6,8,9,12,15,18,21,24,27,30,35 | |||||||

| Surface type | hexa,mesh | |||||||

| Film colour | brown, black, red | |||||||

| Film density, g/m2 | 220g/m2,120g/m2 | |||||||

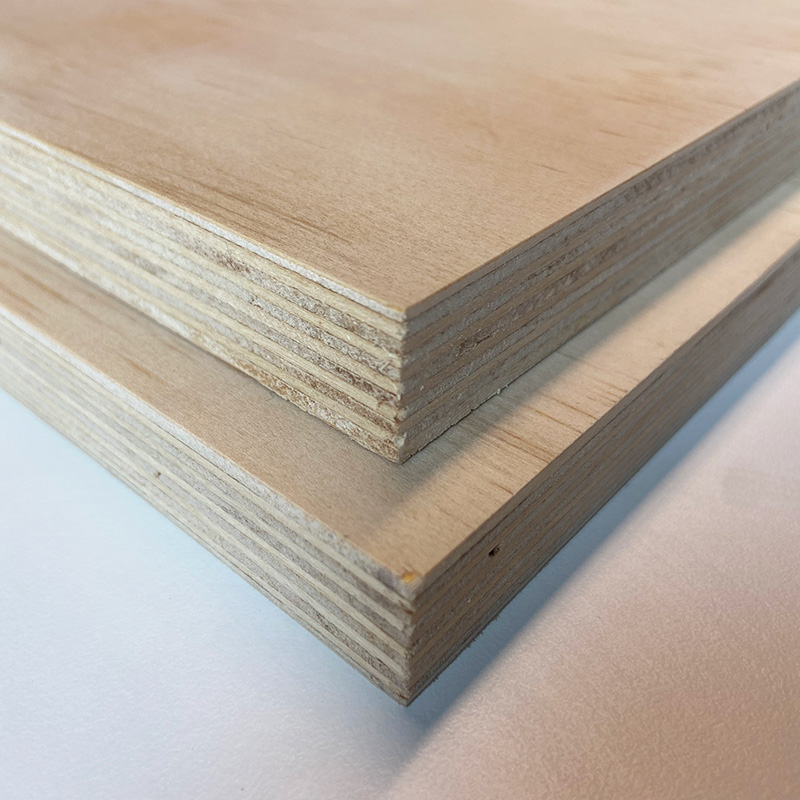

| Core | birch/eucalyptus/combi | |||||||

| Glue | phenolic WBP (type dynea 962T),melamine WBP | |||||||

| Formaldehyde emission class | E1 | |||||||

| Water resistance | high | |||||||

| Density, kg/m3 | 550-700 | |||||||

| Moisture content, % | 5-14 | |||||||

| Edge sealing | acryl-based water resistant paint | |||||||

| Certification | EN 13986, EN 314, EN 635, EN 636, ISO 12465, KS 301, etc. | |||||||

Strength indicators

| Ultimate static bending strength, min Mpa | along the grain of face veneers | 60 | ||||||

| against the grain of face veneers | 30 | |||||||

| Static bending elasticity modulus, min Mpa | along the grain | 6000 | ||||||

| against the grain | 3000 | |||||||

Number of Plies & tolerance

| Thickness(mm) | Number of Plies | Thickness tolerance |

| 6 | 5 | +0.4/-0.5 |

| 8 | 6/7 | +0.4/-0.5 |

| 9 | 7 | +0.4/-0.6 |

| 12 | 9 | +0.5/-0.7 |

| 15 | 11 | +0.6/-0.8 |

| 18 | 13 | +0.6/-0.8 |

| 21 | 15 | +0.8/-1.0 |

| 24 | 17 | +0.9/-1.1 |

| 27 | 19 | +1.0/-1.2 |

| 30 | 21 | +1.1/-1.3 |

| 35 | 25 | +1.1/-1.5 |